History

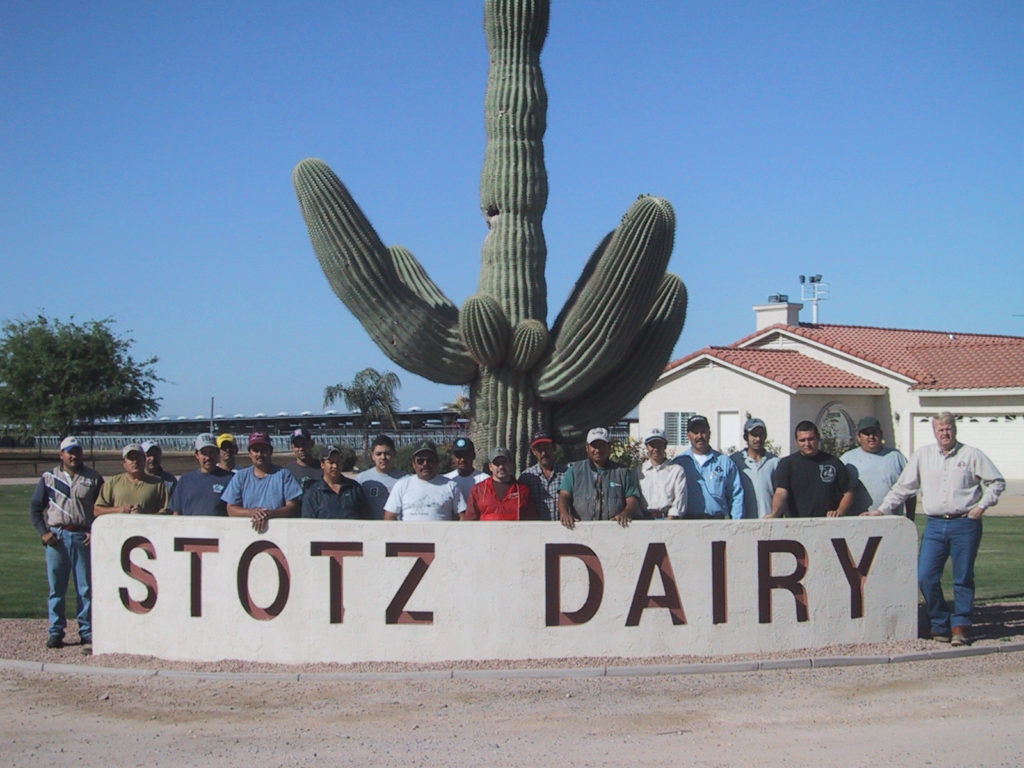

Stotz Dairy is a family owned dairy that was founded in 1981 by the Thompson and Rosztoczy families. It is located in the picturesque Sonoran Desert of central Arizona. The dairy started with 539 cows and 4 employees. Since then, Stotz Dairy and the dairy industry as a whole have seen vast changes. Advancements in technology have helped tremendously in increasing milk production and efficiency.

Stotz Dairy is a family owned dairy that was founded in 1981 by the Thompson and Rosztoczy families. It is located in the picturesque Sonoran Desert of central Arizona. The dairy started with 539 cows and 4 employees. Since then, Stotz Dairy and the dairy industry as a whole have seen vast changes. Advancements in technology have helped tremendously in increasing milk production and efficiency.

Stotz Dairy prides itself in being early adopters of proven technology. Tom Thompson, CEO of Stotz Dairy, has been at the forefront of implementing these new technologies for over three decades. One of the most frequent questions we get is, “how do your cows handle the Arizona heat?” Stotz Dairy has done many cow cooling trials over the years in conjunction with the University of Arizona. The goal is to keep cows as cool and comfortable as possible throughout their entire day in order to maximize their health and production.

In the early 1980’s, computerized evaporative coolers were added to the corrals and milk barn to give the cows relief from the harsh summer temperatures that can exceed 120° F. This technology improved milk production by over 40% during these hot months as well as drastically improving herd health and fertility. These coolers can effectively cool the cows’ environment to the high 60°s when it is over 110° F. Amazingly, despite the harsh temperatures, this technology helps place Arizona as one of the top two states in the country on a milk production per cow basis.

Since the beginning, Stotz Dairy has been a member of the United Dairymen of Arizona milk cooperative. Our job as dairymen is to produce milk of the highest quality. Milk leaves the cow at 101.5° (her body temperature) and we immediately cool it down to 38° with a refrigeration heat exchange process. The milk is then stored in silos on site and awaits pickup by a milk tanker. Around 15 trucks come to Stotz Dairy daily to transport our milk to the UDA processing plant in Tempe, AZ. That is a total of 750,000 pounds or 87,200 gallons every day! UDA is essential for the survival of our dairy as they are responsible for processing, marketing, and selling our milk.

We, as member owners of UDA, have set very strict quality standards for our milk to ensure a safe, high quality, good tasting product with a long shelf life. Each load of milk that arrives at the processing plant is first checked for antibiotic residue. At Stotz Dairy, our method statement is, “Treat each cow like she is our only cow.” Therefore, we treat any cow with an illness in an intensive care hospital barn. As prescribed by our veterinarian, some of these cows are administered antibiotics. All milk from these cows is discarded. When the cow is healed from her illness and the antibiotics are no longer in her system, she is returned to the milking herd. In the extremely remote chance that a cow on antibiotics is accidentally milked into the tank, the antibiotic residue would be detected at UDA before the truck was even unloaded. In this case, the entire load of milk would be discarded.

Once the load of milk passes quality standards, it is unloaded at the plant and is pasteurized and homogenized. Pasteurization is the process of rapidly heating the milk to 161° for 15 seconds. This kills any potentially harmful pathogens in the milk, further ensuring a safe product for consumers. Homogenization is the process of pulverizing the fat globules in milk into much smaller particles. This keeps the milkfat in solution, eliminating the possibility of the cream rising to the top. Our milk is then used to make various products including: fluid milk, Greek yogurt, cheese, ice cream, cream cheese, cheese curds, butter, lactose, ultra-high temperature coffee creamer, and powder milk. These products are then shipped to consumers all around Arizona, throughout the country, or even worldwide.

According to the University of Arizona, Stotz Dairy has been the highest producing herd in Arizona for 24 of the last 30 years. However, milk production per cow is not our only focus. In order to provide fresh dairy products to the increasing population of Phoenix, the dairy has grown. The first major expansion happened in 1995 with the addition of a 60-stall parallel milk barn which brought our cow population up to 6,400 head.

In 2010, Stotz Dairy underwent another major expansion with the purchase of a five-year-old neighboring dairy. In order to maximize biosecurity, ensure excellent genetics, and take advantage of our ability to raise heifers economically, we decided to do the majority of our cow growth from within through the use of sexed semen. At the end of 2016, our expansion reached fruition and we are now milking 9,640 cows with a total herd size of 20,000 head.

Shortly after the purchase of the new dairy in 2010, in order to control some of our inputs, a decision was made to start growing crops for our cows. Our goals when we began farming were to maximize feed quality and provide a cost effective, secure feed source for our dairy. Stotz Farming now grows roughly 50% of the forage needs for our herd. Corn silage, sorghum silage, alfalfa, oats, and beets are the main crops grown for the dairy. A double or triple crop rotation is used on the farmland in order to maximize production and keep our soils healthy. Manure is hauled away from the dairy corrals and spread onto the fields as fertilizer. Crops are harvested either as silage or are fed fresh depending on the needs of the dairy.

Stotz Farming began with 1,300 acres in the Buckeye area. In 2013, an additional farm was purchased in the neighboring town of Gila Bend. This 1,000-acre farm was not a farm at all. In fact, it was all desert land. After clearing the brush and trees, we installed a subsurface drip irrigation system in order to maximize water efficiency and crop production. After a few more acquisitions, our total acreage is now at 3,650.

In order to further improve feed quality, Stotz Harvest was formed in 2013. We now harvest all of our own alfalfa and oats as well as custom harvest alfalfa that is purchased for the dairy from neighboring farmers. Twelve loads of greenchop alfalfa are harvested and hauled to the dairies 365 days a year. Any excess alfalfa beyond the greenchop needs is either baled, drychopped, or put up as haylage by our harvest crew.

Stotz Dairy’s expansion which began in 2010 has increased our work force from 43 employees to 185. A large part of these new employees are Burmese political refugees hired through the International Rescue Committee. We also hire skilled cow care specialists through the use of TN visas. Many of our employees have been with us for over 20 years! We realize that none of our growth and success would be possible without our amazing people. Their passion, dedication, and care for our cows and crops is what makes Stotz Dairy a leader in the dairy industry.